Tungsten Steel Single Thread Milling Cutter | M1-M24 Metric/Imperial Full Specifications | Design Suitable for Stainless Steel/Titanium Alloy

1. Core Technology Advantages

Ultra-high Precision and Surface Finish

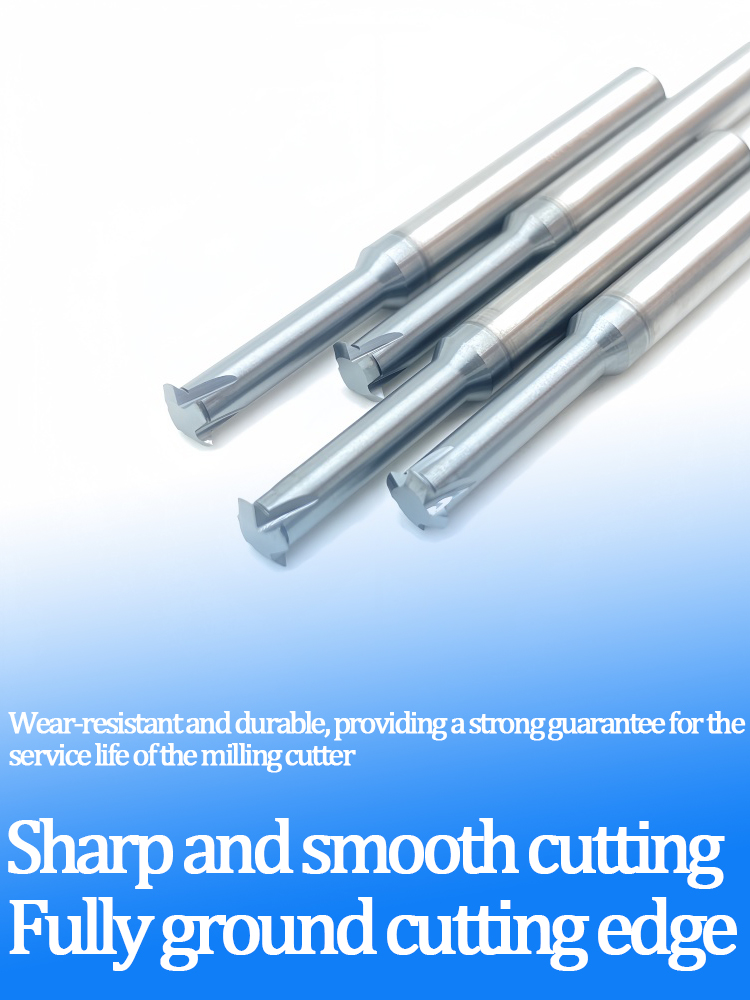

Using 65° tungsten steel alloy and nano-level coating technology, the hardness reaches HRC89, achieving thread processing accuracy of ±0.005mm and surface roughness Ra≤0.8μm, far exceeding the processing effect of traditional taps.

The single-edge spiral design reduces cutting resistance and reduces processing vibration by 30%, which is suitable for thin-walled parts and deep hole processing.

Provides 12 types of tool body forms such as straight shank, extended shank, T-slot, etc., matching turning and milling machine tools and five-axis machining centers.

2. Breakthrough of industry pain points

Solve the bottleneck of traditional tools

Avoid the risk of tap breakage: the chips generated by single-edge milling are powdery, there is no tool entanglement problem, and the scrap rate of workpieces is reduced by 90%.

Blind hole processing capability: It can mill to the bottom of the hole, overcoming the processing difficulties of micro threads of medical devices and deep cavity threads of aerospace.

3. Application scenarios and customer value

Medical devices: titanium alloy bone screws, implant thread processing, in line with ISO 13485 medical certification.

Aerospace: high-stability processing of aircraft engine bolts and high-strength alloy parts.

Precision molds: solve the problems of chipping and precision attenuation in the processing of hard materials (HRC50+)

Single-tooth thread milling cutter: a revolutionary force in the field of precision manufacturing

In the processing of titanium alloy bone screws for medical devices, traditional taps often break due to the high hardness of the material; in the processing of high-strength bolt threads in the aerospace field, multi-tooth milling cutters are limited by the rigid design of fixed pitch. The emergence of single-tooth thread milling cutters is becoming a key technology to solve these industry pain points with its unique single-edge spiral structure and intelligent programming adaptability. The single-tooth thread milling cutter is made of 65° tungsten steel alloy and treated with nano-coating technology. The hardness can reach HRC89, which makes it perform well in processing high-hardness materials such as stainless steel and titanium alloy, and its life is increased by 300% compared with traditional tools4. Its core innovation lies in the single-tooth spiral blade design, which realizes "one-knife" processing through CNC programming, greatly reducing the frequency of tool change, and reducing processing vibration by 30%3. This design breaks through the limitation of traditional tools on fixed pitch, and can flexibly adapt to all specifications of M1-M24 threads, covering the diversified needs of metric fine teeth (such as M6×0.75) to coarse teeth (such as M24×3).

| Product Name | Single Tooth Thread Milling Cutter |

| Number of Teeth | 3-4 Teeth |

| Coating | Balzers Nano Coating |

| Processing Hardness | HRC ≤ 60° |

| Type | Metric |

| Applicable Materials | Stainless Steel, Ductile Iron, Alloy Steel, Die Steel, Titanium Alloy, etc. |

| Machinery | CNC Machining Centers, Engraving Machines, High-Speed Machines, etc. |

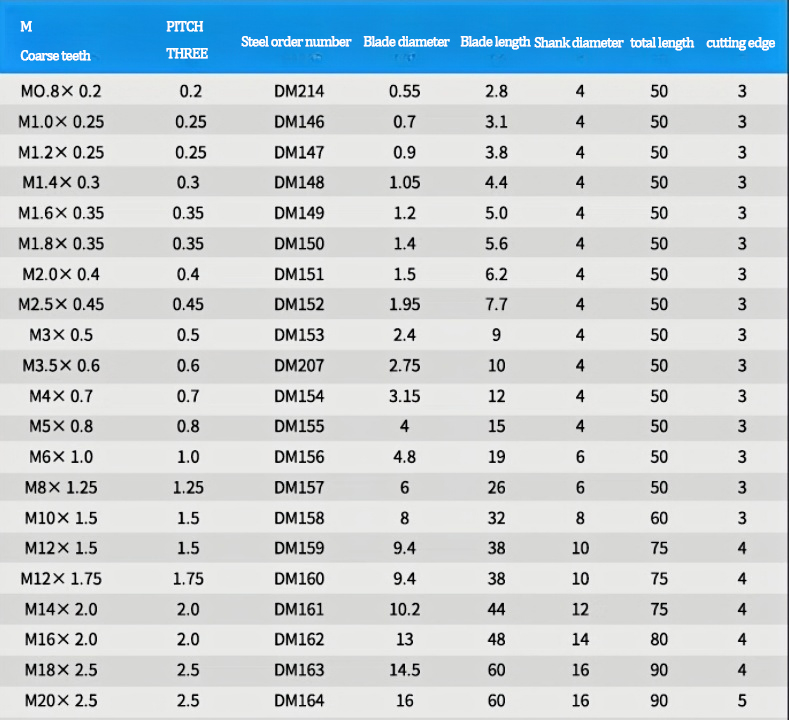

| Coarse teeth | PITCH | Steel order number | Blade diameter | Blade length | hankdiameter | total length | cuitting edge |

| MO.8×0.2 | 0.2 | DM214 | 0.55 | 2.8 | 4 | 50 | 3 |

| M1.0×0.25 | 0.25 | DM146 | 0.7 | 3.1 | 4 | 50 | 3 |

| M1.2×0.25 | 0.25 | DM147 | 0.9 | 3.8 | 4 | 50 | 3 |

| M1.4×0.3 | 0.3 | DM148 | 1.05 | 4.4 | 4 | 50 | 3 |

| M1.6×0.35 | 0.35 | DM149 | 1.2 | 5.0 | 4 | 50 | 3 |

| M1.8×0.35 | 0.35 | DM150 | 1.4 | 5.6 | 4 | 50 | 3 |

| M2.0×0.4 | 0.4 | DM151 | 1.5 | 6.2 | 4 | 50 | 3 |

| M2.5×0.45 | 0.45 | DM152 | 1.95 | 7.7 | 4 | 50 | 3 |

| M3×0.5 | 0.5 | DM153 | 2.4 | 9 | 4 | 50 | 3 |

| M3.5×0.6 | 0.6 | DM207 | 2.75 | 10 | 4 | 50 | 3 |

| M4×0.7 | 0.7 | DM154 | 3.15 | 12 | 4 | 50 | 3 |

| M5×0.8 | 0.8 | DM155 | 4 | 15 | 4 | 50 | 3 |

| M6×1.0 | 1.0 | DM156 | 4.8 | 19 | 6 | 50 | 3 |

| M8×1.25 | 125 | DM157 | 6 | 26 | 6 | 50 | 3 |

| M10×1.5 | 1.5 | DM158 | 8 | 32 | 8 | 60 | 3 |

| M12×1.5 | 1.5 | DM159 | 9.4 | 38 | 10 | 75 | 4 |

| M12×1.75 | 1.75 | DM160 | 9.4 | 38 | 10 | 75 | 4 |

| M14×2.0 | 2.0 | DM161 | 10.2 | 44 | 12 | 75 | 4 |

| M16×2.0 | 2.0 | DM162 | 13 | 48 | 14 | 80 | 4 |

| M18×2.5 | 2.5 | DM163 | 14.5 | 60 | 16 | 90 | 4 |

| M20×2.5 | 2.5 | DM164 | 16 | 60 | 16 | 90 | 5 |

In the field of medical devices, single-thread thread milling cutters have become the preferred tool for thread processing of titanium alloy implants with a repeatable positioning accuracy of ±0.005mm. For example, the surface roughness of the internal thread processing of bone screws with a diameter of only 1.2mm can be controlled at Ra≤0.8μm, far exceeding the ISO 13485 medical standard.

The aerospace field benefits from the tool's deep hole processing capabilities. In the M18 deep cavity thread processing of a certain model of aircraft engine parts, the single-thread milling cutter completed the thread milling with a depth of 5 times the diameter through the extended handle design, avoiding the risk of broken blades of traditional taps. In addition, in precision mold manufacturing, the tool successfully solved the problem of chipping blades during the processing of cemented carbide materials, and increased the thread qualification rate from 78% to 98%.

3. Market positioning: technology dividends and global layout

Compared with three-thread/full-thread milling cutters, the single-thread design reduces the procurement cost by 30%, and the life is more than 10 times that of traditional taps, making it have a significant cost-effective advantage in small and medium-sized batch production. At present, the product has passed ISO 9001 and AS9100 aerospace certification, and obtained utility model patents (such as CN213410688U). Its detachable cutter head structure greatly improves the convenience of maintenance.

In terms of globalization strategy, the manufacturer provides technical documents in Chinese/English/German/Spanish, covering platforms such as Alibaba International Station and Amazon Industrial Products, and launched the traditional Chinese version of "Single-flute Thread Milling Cutter" for the Taiwan and Hong Kong markets, accurately reaching multilingual customer groups.

IV. Industry Trends: Co-evolution of Intelligent Manufacturing

As CNC machine tools develop towards high precision and less manpower, single-tooth thread milling cutters are deeply integrated with AI process libraries. An automotive parts manufacturer has increased the efficiency of titanium alloy thread processing by 25% and reduced tool loss by 18% by implanting a processing parameter optimization algorithm9. In the future, the popularization of 5G+ industrial Internet will promote the application of remote tool status monitoring technology and further release its technical potential.

From micro medical devices to macro aviation components, single-tooth thread milling cutters have reconstructed the technical boundaries of thread processing with their precision, flexibility and durability. Driven by smart manufacturing and material upgrades, this tool will continue to empower high-end manufacturing and write a new chapter in the field of precision machining.

- anterior : Ferramenta de Tungstênio de Tungstênio de Tungstênio de Tungstênio CNC CNC BAR 45 °/60 ° HAXE

- próximo : Corte de moagem redonda de nariz redondo de aço de tungstênio - moinho de extremidade de carboneto CNC de alta velocidade para metal/madeira - ferramenta de corte de precisão industrial